EPIC WOODYS DAY + How To Tips

Yesterday was a very big day at the world headquarters of waitematawoodys – we passed the 10,000,000 views mark. Seems just yesterday when I watch the counter tick past 1,000 and thought – ‘wow, maybe other people are interested in what I am’.

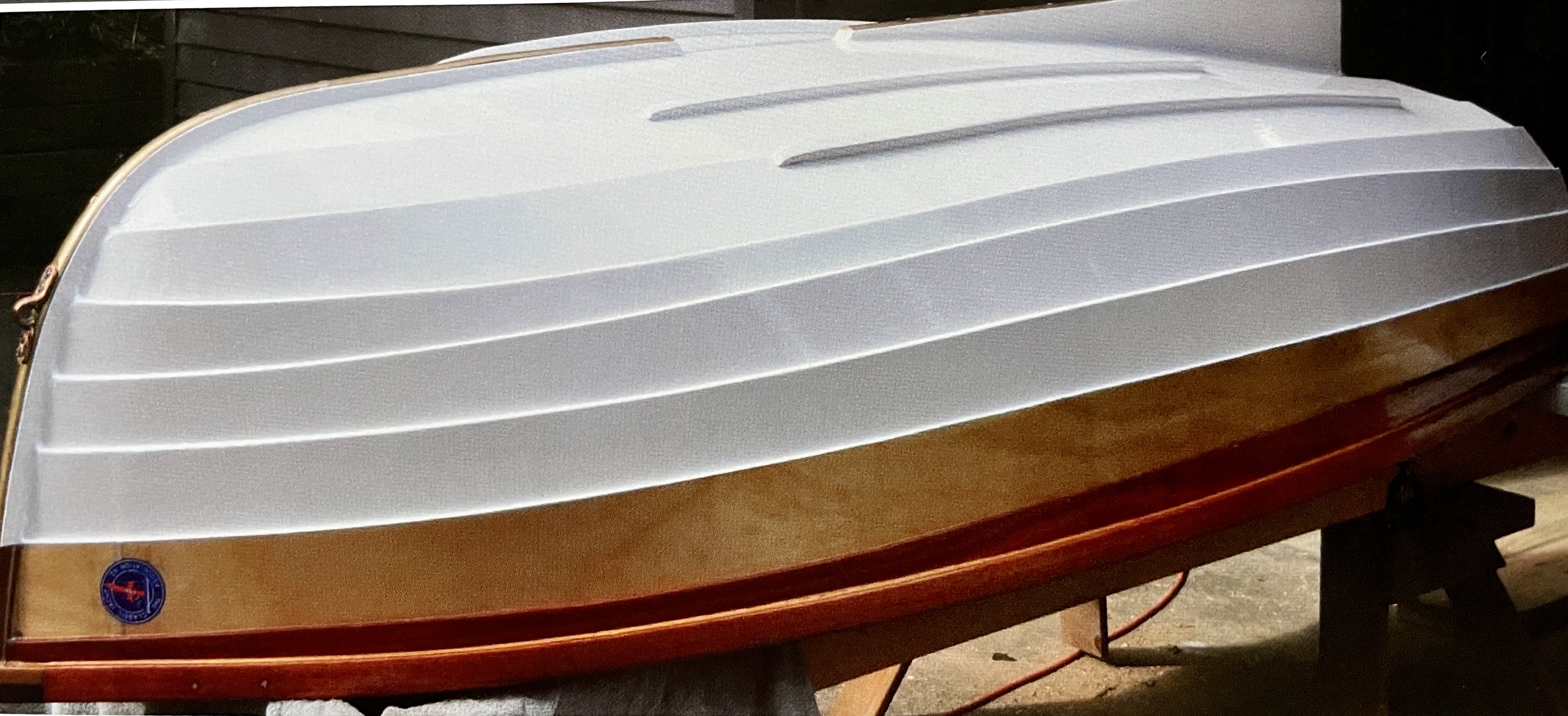

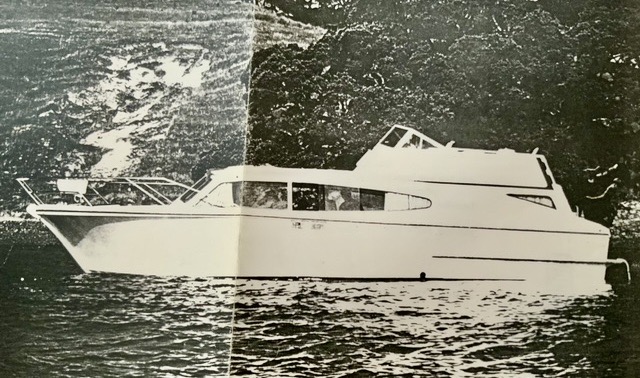

Some history – In the beginning I chose a blog format not a website, forum or a facebook page , this decision was a winner as using a blog allows me to keep the site pure to its DNA –

the study & appreciation of wooden boats. We do this via telling stories about the history of our classic wooden boats, the craftsman who built them & characters that owned & crewed on them. Along the way the site has morphed into a resource tool for classic woody boats and everything else connected to the movement. On any given day approx. 1/2 the site visitation is research driven e.g. people looking for a particular boat , a person or help with a problem. Covid did amazing things for the site – the number of individuals visiting the site and signing up for the daily email alerts more than doubled and most of them liked what they saw / read and have stuck around. I made a decision a while ago and commenced loading a lot more stories on boats that maybe a few years ago wouldn’t have passed the grade in terms of the wow factor, the reason being to build a more extensive ‘library ‘ of content – so if sometimes you think “what the …. how did that make it onto WW, its there for historical reasons 🙂

I’d be lying if I told you writing a daily woody story and maintaining the site was undemanding – as the numbers have grown the email inbox swells, so I apologise if my email etiquette isn’t always to your liking.

Some Suggestions On How To Best Use The Site

1. If are aren’t already – sign on to receive email alerts when new stories go live

2. Use the COMMENTS section – there is no such thing as a dumb question

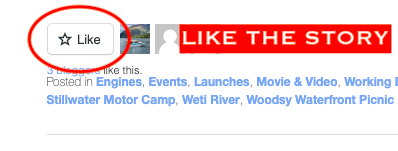

3. LIKE (click) a story, that way if new content or comments are added, you’ll get an alert

4. Use the OLDER POSTS button, the site only shows a limited number of current stories, this speeds up your access to the site

5. Use the SEARCH box to find anything on the site

6. Use the POPULAR TAGS to find the most viewed content

7. Use the FIND STUFF tags to search by category e.g. all work boat stories

8. Use the SHARE links e.g. email the story to a friend, post the story on your facebook

9. Buy the WW merchandise – it helps oil the wheels – hosting over 50,000 images in cyber space isn’t cheap and WW has to pay to stop advertisements for products like Viagra and hair transplants appearing on the site 🙂 https://waitematawoodys.com/2021/11/11/58095/

10. Support the advertisers on site

11. If you have a business in the marine game – consider advertising on the site.

AND LASTLY – Send in any photos or information you have, it might not be enough for a story, but more often than not someone else sends in something and -snap – combined we have a story

Big thanks to everyone for helping make waitematawoodys what it is and special thanks to those that send in material