TIME – 4 Sale

TIME – 4 Sale

SS DUKE of MARLBOROUGH

I recently stumbled across the above photo of the steam ship – Duke of Marlborough and knowing nothing about her put a call into Russell Ward aka Mr Steam. The man is never embarrassed to speak so – take it away Russell, WW is all yours…..

“Once, 30+ years ago, I built up a steamboat called “Gypsy”. So pull up a chair, warm yourselves by the fire and I’ll tell you a story which isn’t about “Gypsy” at all, it’s about the “James Torrey” which became the “Duke of Marlborough”.

But, through “Gypsy”, I met one Lloyd Lewis of Lake Tarawera. He was an ardent enthusiast for steamy things (who wouldn’t be – living on Lake Tarawera.) Lloyd had made a steamer up out of a hull I had sold him a year or so previously and really had the steamboat bug badly. As the late Pete Culler (he wrote a lot about boats and he was a wise man) said “It’s awful, don’t go near it or you are hooked.” And you can’t argue with facts like that, folks. Suffice to say Lloyd got steam enginitis in a big way.

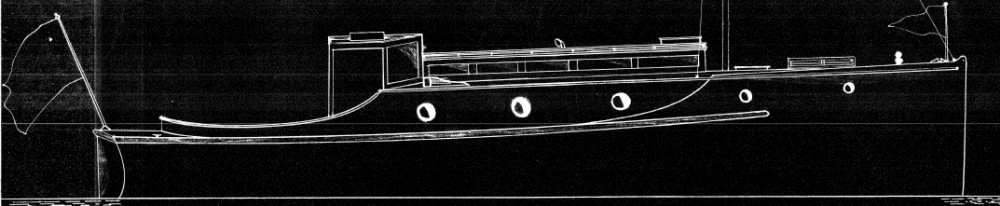

He had Wellington naval architect Bruce Askew design a hull for a 36’ steam vessel following the style of the early 1900 steam boats The steel hull was built in 1987 by Gordon Clark and Brian Starrock in New Plymouth and shipped to Rotorua for Lloyd to complete. He did a fine aesthetic job. She was launched as “James Torrey” and he used her to take fishing tours on the lake. The lads appreciated the warmth from the boiler at times.

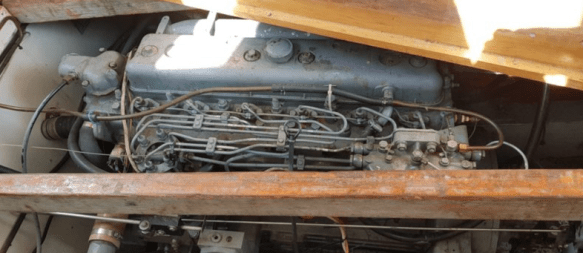

Lloyd built the engine – an English design by A.A. Leake and a dashed good looker it is -a traditional open compound, driving a 28” by 42” propeller giving a service speed of 6 knots. A piston valve is fitted to the high pressure cylinder and a balanced slide valve on the low pressure one. It has cross-head driven twin feed pumps and air pump. Exhaust is through a feed-water heater to a keel condenser. There you feel a lot better for knowing that.

But to sum up, working on salt water, you have to condense the exhaust steam or you run out of feedwater real quick. Besides, condensing gives you a useful addition to the power through the vacuum created which, in essence, sucks the piston while the steam pushes.

The steam is provided by a Kingdon type boiler (1900’s Simpson Strickland design) built by Langley Engineering in the U.K and, since you didn’t really want to know, It is a vertical fire-tube type, 34 inches high by 30 inches diameter over lagging, has 3.4 square feet of grate area and has 84 square feet of heating surface. She burns coal and there is nothing better.

Lloyd had quite job actually getting Ed Langley to dispatch the finished boiler although it had been long since paid for. Ed had had his delivery problems over the years…. Legend has it that, in frustration (remember communication was all letters and phone calls that had to be booked well ahead in those prehistoric times); Lloyd flew over to the UK and turned up at the works just ahead of the receiver. Seeing the likelihood of his investment coming to nothing, he took matters into his own hands and loaded the boiler up himself. Lloyd just wasn’t the sort of man to argue with and got his boiler. It is a very handsome job.

Anyway after a number of years, Lloyd tired of his steamboat and Roger Frazer took her to Picton. He renamed her “Duke of Marlborough” and did a lot of restoration which is a credit to him. He has been taking passengers out of Picton for some time. I’m sure the passengers appreciate the boiler’s warmth even more that the Lake Tarawera types.”

I understand she may be for sale………

WoodenBoat Magazine Interview #3

This week WB editor Matt Murphy interviews Harold Burnham in a live discussion of how, for nearly three decades, he has been instrumental in revitalizing the shipbuilding and maritime culture of his region by designing, building, and rehabilitating traditional vessels for cultural tourism. Harold is an 11th-generation shipwright, and has, at various times, also been a sawyer, mariner, model maker, and sail maker.

Chatting with Tinopai (2hrs north of Auckland) based woody Greg Schultz he tells me advancing old age has forced him to make the reluctant decision to pass on one of my most prized possessions.

Greg built this boat about 10 yrs ago off the original 1905 Arch Logan plans (modified by Chapman1921). Construction is clinker lapstrake using 6mm ply with epoxy glued laps which gives a good lightweight watertight hull (originals leaked like sieves and weighed a ton). All other timbers are kauri and totara. He also added 3 buoyancy compartments for added safety (2 side seats & forward compartment all epoxy sealed inside). Greg commented that she has only been sailed approx. a dozen times.

The Silver Fern class (12’6″) was designed as a training boat for teenagers before they moved on to the bigger M class and is therefore almost a miniature ‘Emmie’.

Spars and rigging are s/s and sails by Fife. Pivoting centerboard and rudder for shallow water sailing. Permanent reef lines for shortening sail without coming ashore.

Woodys this is a stunning boat to both look at and sail so if you are frustrated with paying big marina fees and the hassles of organizing crew – maybe now is the time to add a woody to the fleet so that you can sail single handed or take the grand kids for a sail.

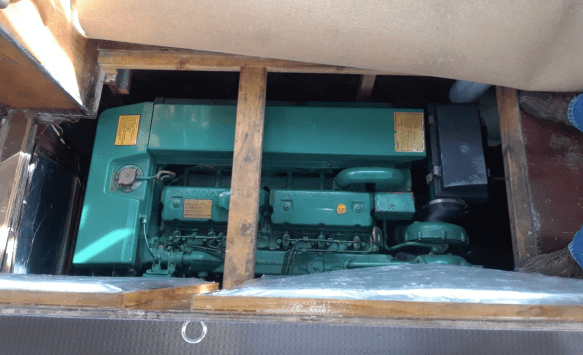

ERINOR – A Peek Down Below

NGARURUA

A10 – Thelma / A7 – Rainbow

A7 – Thelma / A2 – Rawhiti

A16 – Little Jim

Hopefully when you read this I’ll be enjoying breakfast aboard Raindance somewhere near Waiheke Island, having had an enjoyable day / evening at the Woodys Classics BBQ & Pizza lunch at Little Oneroa,