BUILDING THE CLASSIC LAUNCH – GAY MERILYN (Tee Gee > Stokin) – Part Two

Following on from yesterdays story on the launch – GAY MERILYN, today thanks to more input from Gwenyth Frear we get an insight into the building of the launch – we hand over to Gwenyth to tell the story – Enjoy (photo ex 35mm slides)

“We had always had boats of one sort or another, and owned the launch LORNA DOONE at this time, but that’s another story! Keith decided he would build another one more to his liking….

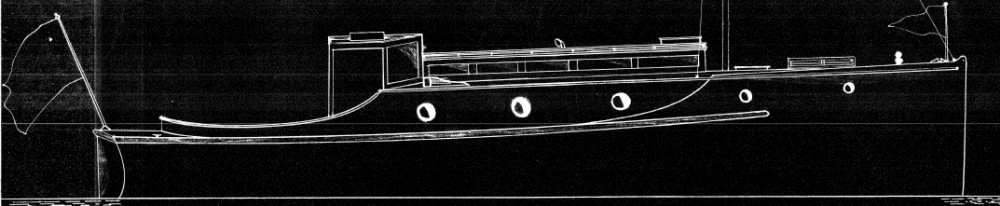

Keith thought he would like to build launch about eleven and half metres long, so when we went to Auckland in late 1969, we went to one of the large bookshops to see if we could find some plans. But as we were starting to look at design books, there didn’t seem to be anything he wanted. Someone overheard us discussing plans and the pros and cons of the matter, and tapped Keith on the shoulder. “You should get in touch with John Lidgard he’s the man who can help you”, he said. So, no sooner said than done!

We found out where he was and went to see him in his workshop and came home with a set of plans, a bandsaw, an abundance of enthusiasm, and not much else. In the course of our looking around, we made the acquaintance of one of the workmen working for John. He said he came up to Cooper’s Beach each year for his holidays, and that he would look us up and see how Keith was getting on. No doubt he was fascinated by the idea of a raw farmer tackling a tradesman’s job with no know-how, and no equipment!!

Keith mentioned to the manager of Northland Motors in Kaitaia, that he was thinking of building a boat, and the next thing we got notice that there was a motor sitting in the shop waiting for us!! Now we were well committed to the job!! So Keith and Barry (my brother) got down on the floor at home and started drawing out the plans from the instructions Keith had been given.

The Big Building Project

The first thing to do was to order the timber from Lane and Sons’ timber mill at Totara North. Keith was able to get timber from the last of the kauri trees that were milled there before the restrictions came in that no more kauri was to be cut down.

We were milking a sizeable herd of cows at this time (two people in a walk through cowshed) , and there was all the usual farm work to be done as usual, so we knew it would be a slow job.

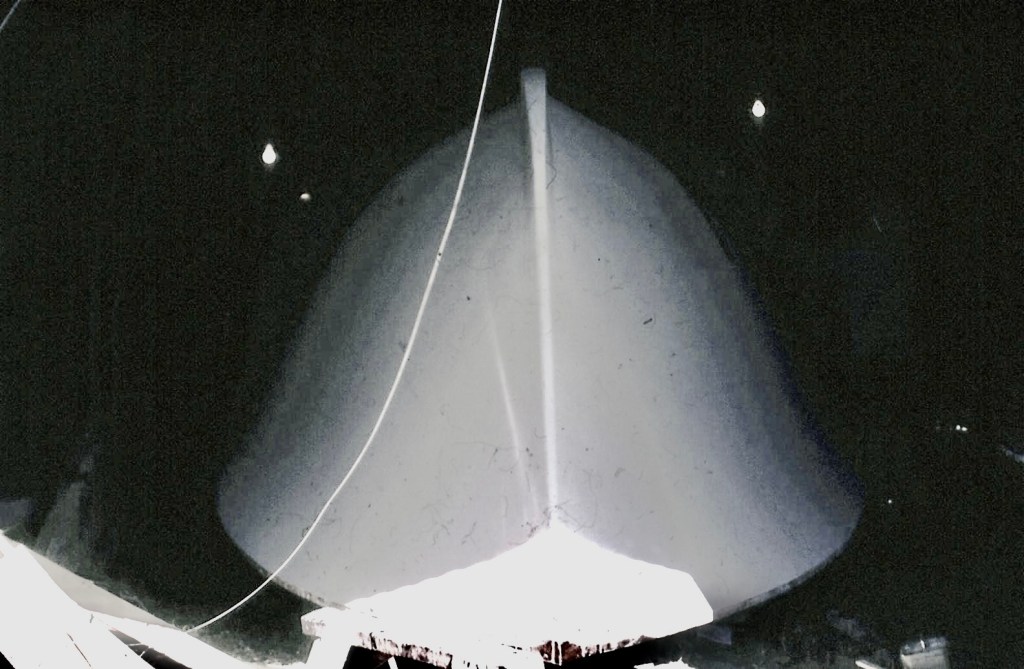

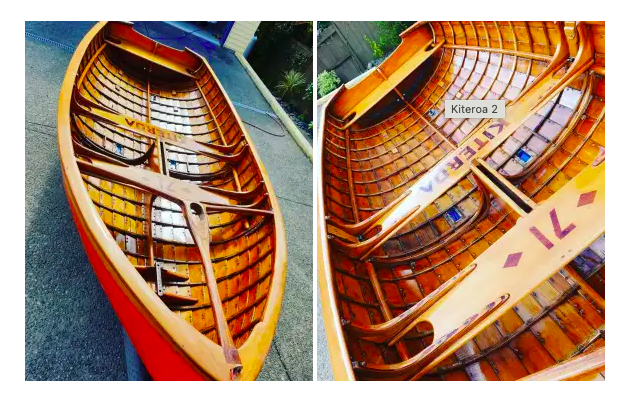

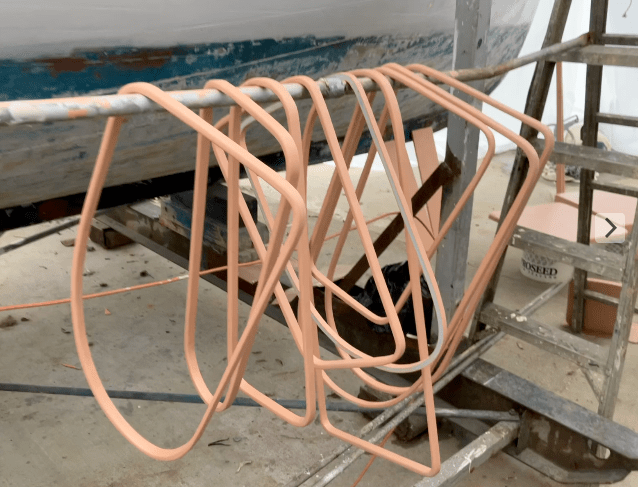

The question was where to build it? That was no problem….there was the round barn next to the cowshed. So it was cleaned out and the work began. The first job was to put the building frames in place, starting at the bow of the boat, and placed in order the full length of the boat. Once this was done, then the stringers went on, all screwed and glued into place. The four skins of the kauri went on, one by one, placed diagonally a different way each time. This was the most tedious job of the lot. For a whole twelve months, nothing was done after the first skin went on, until an older man took pity on him and came to give a hand now and then. After that was done, then the fibre-glassing was done….the first coat of resin was put on over fibre-glass cloth, sanded down, and then another coat of resin before the final coat of white fibre-glass paint.

In May of 1973, the hull was ready to be turned over. The keel was in place with the hole for the rudder bar already done. The day for turning it over came, and was a matter of great curiosity for the neighbours. It proved to be a very long job even with some of their help. An endless chain was used for this, and it went up inch by inch, finally making it after eight or nine long hours.

The dairy cows were sold that year, with beef cattle replacing them. So Keith was able to work full time on the boat after that. The motor went in (Ford 110 hp) and the work continued uninterrupted until it was completed by September 1974.

Then getting her out of the shed was the big question on everyone’s mind! How could it possibly be done? The gap between the barn and the cowshed wasn’t as long as the boat, so what was Keith going to do about it? But it was done slowly with the tractor, and the help of grease on large pieces of plywood, and the trailer being jacked around bit by bit on that.

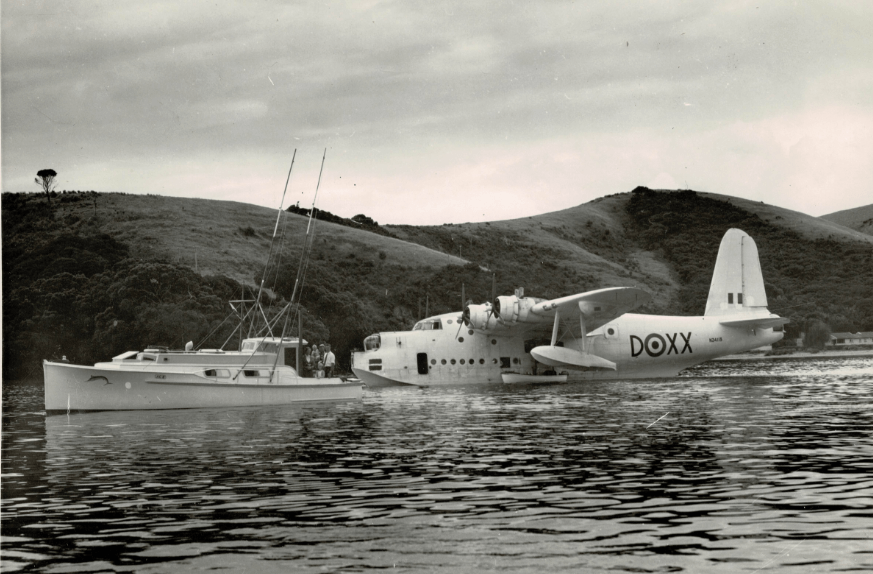

She waited on the trailer until early the next morning, when she was towed down the road to the ramp at Totara North before the traffic began. Then it was just a matter of waiting for the tide to come in to launch her. By this time there were quite a few onlookers, all asking the same question….will she float straight?

The tractor backed into the water, and she slid into the tide with a waiting fishing boat ready to take her to her mooring. She floated perfectly, right on the water line, as she was meant to.

At Christmas time that year, when the man from Auckland came up, we gave him and his family a trip down the Whangaroa Harbour. He looked it all over from a tradesman’s point of view, and said, ‘Well, if anyone had told me that a farmer with no boat building experience, and no tools apart from a band-saw and hammer could produce something like this, I would never have believed them’

We felt that this was high praise indeed.”