OKURA GIGS

photos & details ex Darren Arthur

We did a post on ww a little while ago about ‘Seabird’ dinghies & this generated chat & subsequent comments about the ‘Okura Gig’. This sparked Darren to contact his wife’s uncle – Dennis Hart, who with his late brother Ray ran Hart Brothers Marine and were behind the Okura Gigs. Darren encouraged Dennis to document their history.

Darren asked me that given that the boats we not wood, was it a potential ww story – after a quick peek at the photos – I replied that there was more than enough wood & bronze to get the ww tick 😉

I have published Dennis’s story below word for word, its a great tale & combined with the above collection of older & recent photos is a cracker read. Enjoy 🙂

THE OKURA GIG: A Brief History By Dennis Hart

Background

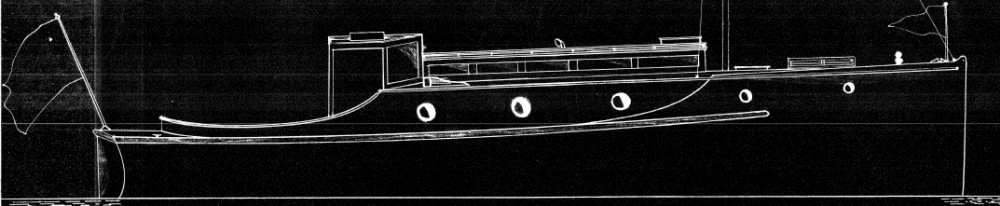

During the late 1800’s the area at Silverdale now known as Millwater included the Grut (pronounced Grew) farm which had access to the Orewa Estuary. Mr Grut had a 10 foot kauri clinker rowing boat, understood to have been built by Bailey & Lowe at Sulphur Point, Northcote. The boat was mostly used for net fishing. Charles St.Croix Grut and Alec Grut later inherited the farm and continued farming until the 1960’s ?

Dennis believes Croix and his wife Merle had the 38ft Wollacott design yacht Iorana, built by Don Wood at his yard in the Orewa Estuary. However the memory can play tricks over time & Dennis would be interested to learn if he is correct in this. The couple then in their late 60’s were the first Weiti Yacht Club members to circumnavigate the globe.

Croix brought the boat to my brother Ray and I at Hart Bros Marine in the mid to late 70’s for a full restoration to its original configuration as the 70 plus years had taken their toll. We duly completed the ‘no expenses spared’ job resulting in a very pretty and sound rowing boat. We negotiated a deal whereby we could use the boat as a plug and take a mould from it in order to produce the boat in fibreglass , We made no charge for the restoration returning it to Croix and Alex with a fibreglass replica rowing boat each for their general use. The original boat was retired.

I tried to locate the original boat and was told by Croix that he had entrusted it to a gentleman who had promised to donate it to the Maritime Museum. On enquiring there I was told that no such boat had been received. Croix Passed away in November 2012 aged 94.

Building the OG

Because of the tumblehome created by the very pretty wineglass transom the mould had to be in two parts. The original boat had no centrecase so a slot was cut in the keel and a case was moulded in -situ at the same time as fitting the buoyancy thwarts and stern benches . A galvanised steel swinging plate was hinged at the top forward point, raised and lowered by a stainless wire. After release from the mould Kwila slats were fitted to the thwarts, the inner and outer gun’les were copper riveted together, the thwart and lodging knees fixed in place followed by the remainder of the fit-out . Two rowing positions were provided, the forw’d pair provided fitting for the side stays.

The rig

The sails were kept as traditional as possible by using ‘tanbark’ coloured sail cloth and braided lacings. The oregon spars were made so that they would fit inside the boat, when not in use. This worked well as a handy sized main was set with the peak well above the mast top. This, coupled, with a boom that overhung the transom and a jib tacked to a short sprit, giving plenty of sail. Many of the fittings that controlled the running rigging (cleats and blocks, were made by hand or modified from Harken traditional range. All other fittings were sourced from the depths of Fosters basement or were bespoke by us of copper, brass or bronze. The gaff jaws were covered in leather. Rope sheets were a light tan poly. The gaff halyard was rove to a bridle to make setting the main more simple.

Development

Like the old harbour ferries the OG has a balanced waterline with fine ends so does not drag water at the transom as the boats bottom lifts the transom clear of the water at the stem of the wineglass. Fit-out of these boats was kept to an affordable minimum at the time. As production continued we made some minor modifications and improvements, i.e. separate peak and throat halyards to give better shape control to the main, reefing points and tackle for the main, a change from cane rings to lacing on the luff. The rudder is if fixed shape with a swivelling tiller, its bottom edge does not extend below the keel line which allows safe beaching.

The sail plan was easy enough to balance on paper. In practice it showed a slight weather-helm in fresh airs which was easily adjusted by swinging the centreplate back, flattening or easing the sails.

Production

The Okura Gig became a ’boutique’ activity. As a result of the boat tax being imposed in 1979 we reduced the size and scope of our business and closed our fibreglass manufacturing operations and moved our boat shop into the mould shop. We had built about 55 OG’s between 1978 and 1981. The moulds were taken by Dinghy Developments who resumed production giving the OG a Seabird name. I believe that they took their version to USA west coast boat shows where they were warmly received. I have no idea how many more were built.

I have two OG’s, No. 41 and No 49. One had spent about 35 years in a wet boatshed at Lake Rotoiti, it required a complete grind off of the osmosis damage before refitting. The other is our long time family boat. I have refitted them both to a much higher standard than the originals. They are currently in my shed at Whangaparaoa. I still sail OG49 occasionally and still find it enjoyable. It really romps sailing just off the wind with the peak halyard eased . OG 41 is too pretty to put in the water. It would make a fine centre piece in a large lounge.

Croix Grut got to see OG’s 41 & 49 restored and fully rigged before he passed away. Photo below.

Foot note:

I was fortunate to have served my apprenticeship at the Devonport Naval Dockyard commencing in 1958. Marty Martinengo was in the same intake as I, as was Denis Cantell, in 1958. We have enjoyed a very solid friendship ever since, as we do with many of the apprentices who were indentured before or since us. The Dockyard provided a very traditional training in all aspects of boatbuilding and shipwrighting . It was a very competitive environment with up to 14 apprentices at any one time. My brother Ray Served his time at Lidgard’s and Lane’s before moving to Max Carter. He moved to Whangaparaoa about 1968 where he started boatbuilding. I joined him in 1972.

Below is an article reproduced from Sea Spray magazine Sept 1979