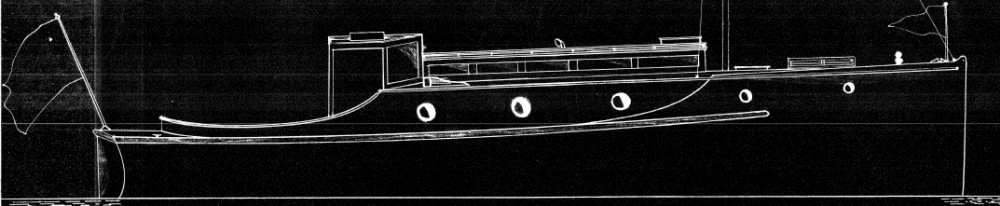

Mosquito Craft Dinghy

details ex Geoff Brebner

OK woodys, who has one of these under the house?

Geoff found the old advertisement below & wondered how many of us remember the little 9ft Mosquito Craft moulded ply dinghy popular as a tender from the late ’40’s through to the mid ’60s. Geoff’s late brother-in-law Hector George was sent by his father Geoff to Davison’s in Vancouver to learn the method of of pressure-moulding with veneer and marine glue. This was in about 1948.The same technique was used during WW2 with the Mosquito bomber, hence the name.

The George family started building them at their home at Tamaki Drive Kohimarama before moving to a factory at Ellerslie. The design of the 9 footer was the prize winner of a RNZYS competition for a yacht tender “way back when”. Geoff was led to believe Bill Couldrey was the winning designer, but is prepared to be corrected on that. Incidently, the George and Couldrey families were related by marriage.

The boats were laminated up over a very heavy solid wooden mould out of four layers of 1/16th veneer, with the apron and kelson integral, then put in a large rubber bag which was pulled down to 30 inches of vacuum until the Aerodux glue cured. Seats, gunwhales and tuck were fitted to the finished shell. Later on a 12 ft and a 10’6″ model were also built.They were produced up until 1965 when the cheaper glass-fibre boats found favour.

Geoff can’t recall the figure, but over 900 of the 9 footers were built. Geoff worked there for eleven years & his sister sister’s family still own the first and the last of the 9ft line.

Geoff thinks the 2nd one built was the tender on Harold George’s VICTORY A8.

There must be a few out there tucked away at the back of the shed.

Harold Kidd Input

The Mosquito dinghies were built in quite a different manner from the “cold-moulded” veneer dinghies. As Geoff describes above the Mosquitos were much more elaborately manufactured than the Lidgard type. There were a lot of the latter built. All that was needed was a good sturdy mould, a supply of straight-grained veneer (often pinus radiata), some Aerodux resorcinol raspberry jam adhesive and a staple gun.

Jack Logan produced heaps of them and many backyard builders whacked them out. I used to help my mate Barry Brickell’s father, Maurice, build them at Tui Street Devonport and went on to use the same technology with John Chapple to build several racing 12 footers and that became almost the standard construction technique for one-off and volume centreboarders, especially Des Townson’s famous Zephyrs and Mistrals.

But the Mosquito craft were the pioneers and arguably the best.

The fuselage of the de Havilland Mosquito (DH98) was originally built of a birch/balsa sandwich using CASEIN glue which was all they had when it was designed in 1938. It caused problems in hot humid conditions by unpeeling. However de Havilland developed urea formaldehyde glues, later available commercially as Aerolite, which aced that issue. The Mosquito wasn’t the first plane to use that construction. I used to fly and part-own a de Havilland Moth Minor (DH94) ZK AKM, which was cold-moulded with casein. She’s still flying happily with no fuselage issues after 77 years.

21/02/2015 Photo ex Darren Arthur

Darren commented that the oil on the transom was the result of running a “Seamaster 400”. A rather odd ball outboard that used an air cooled Tecumseh lawnmower engine. Noisy, heavy, smelly and leaky were some of the more polite adjectives Darren recalls his father using to describe it 🙂

24/02/2015 – story & photos from Roger Lacey

My father bought a 12′ Mosquito craft in about 1969. It was a couple of years old and had a 7.5hp Archimedes Electrolux motor that used to eat spark plugs for breakfast. We used it for fishing in the Waitemata and also at Lake Rotoiti where I learned to row. When my parents bought a bach in Turangi we moved the boat down there but not before sanding back the outside and giving it a coat of epoxy resin, which in hindsight probably saved it. The boat caught many times its weight in trout and made both an ideal fly fishing platform and a stealthy trolling vessel over the shallow weed beds near Tokkanu and at the other smaller lakes nearby. The unreliable Electrolux was replaced by an infernal 2.5hp air-cooled Tas outboard which provided just enough power to motor up the lower reaches of the Tongariro River but was useless for trolling so we rowed it most of the time. In the late ’90s my dad sold the boat with the bach without consulting me so I tracked down the new owner and bought it off him, took it home and restored it. As I didn’t have room for yet another boat I ended up selling it to a friend who has it still. He recently found some rot in it, got it professionally repaired and fitted an new foredeck. It is currently awaiting paint.