CLASSIC LAUNCH – LADY CAROLE RESTORATION – UPDATE #4

Today co-owner Patrick Crawshaw walks us thru the latest work, different layout today, might make it easier to follow.

The last couple of weeks have been focussed on getting the sanding finished for first coat and the wood work finished. The forward hatch, which had been blocked up was re-instated. Tthe forward cabin, where the mast once was had been opened up to make way for a hatch. Two of the ribs had been cut into and this was compromising the strength. So, ribs were replace and the hatch filled in so that the mast can go back to its original location.

The main cabin hatch (shown below) which is above the helm had to be moved inward to allow for the railings to match the other side – from front to back. At some stage, it had been cut too close to the port side and so the railings had to start back behind the hatch which looked awful. This is about the lines – again.

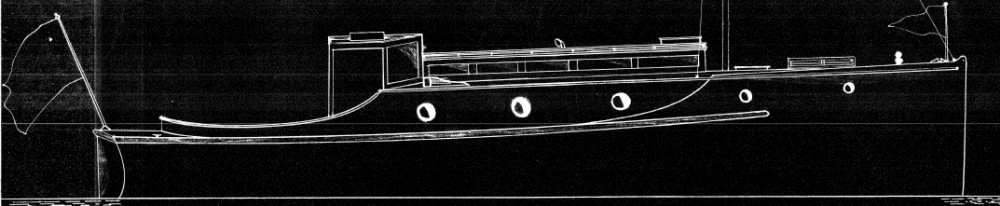

The windows have been a complex and long process. Firstly, we had to find the old curved line which ran along the side connecting the forward cabin to the aft curve.

We had to completely fill the existing windows in so that we could draw that line. Once that was drawn, we could then find out where the windows (from the photograph above) once were. The filled in ply was then taken out and cut to the new window lines. Then they had to be rebated for the glass to then be glued in. Next week is the glass templates and once the glass is in, we will have to cut the trims to go around the windows… The windows have been the most complex part of the job with so many elements and stages to the process. It’s so important we get this right, as they are crucial to the lines of the boat, and we can only work off this photo and a few other tell tale signs.

Rod holders…such fun getting the angle right so they are flush on to the transom.

Discover more from waitematawoodys.com #1 for classic wooden boat stories, info, advice & news - updated daily - 14+ million views

Subscribe to get the latest posts sent to your email.

Yes, I can see a lot of hard work and some of the changes are so very subtle. A good effort.

I do have reservations about the forward hatch. It’s so very rare to find one that doesn’t leak water in a short sea that we so often get in the Hauraki Gulf. This is most likely why it was filled in previously. But the boat needs air flow and this will help. Also of course technology may come to the rescue here?

Vaughan Kearns

Ruapehu Sawmills

LikeLike

Respect and encouragement for returning a real looker to a real looker – enjoying your story!

LikeLike